Up until now, air blast rooms have long been the industry standard for abrasive blasting of large parts up to 10’ x 12’ simply due to the scalability offered when enclosing the human operator within the blast chamber. But at Gibson we like to ask, “What if there is a better way?”

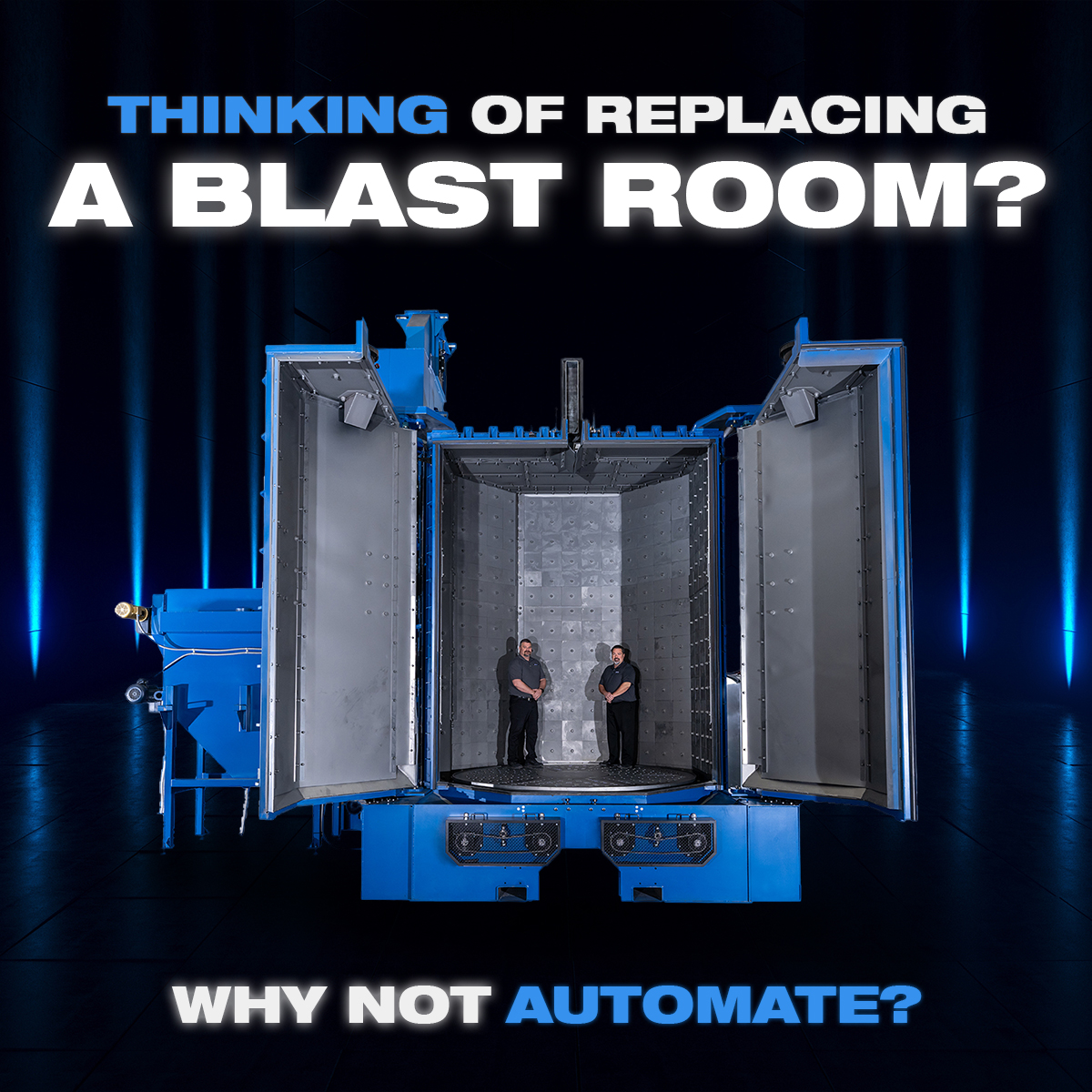

The answer is the TB120XT, an extra-large, extra tall wheel blast machine incorporating a heavy duty rotating table within the blast chamber that can accommodate parts up to 10 feet wide x 12 feet tall and 10,000 lbs! At that size, this machine essentially replaces most air blast rooms with an automated wheel blast solution that is engineered for convenience, operator safety, efficiency, and profitability. Some of the primary benefits of wheel blast automation compared to blast rooms include improved operator safety, lower process air consumption (lower energy costs), and higher overall quality.

| Wheel Blast Automation | Air Blast Rooms | |

|---|---|---|

| Energy efficiency | Higher | Lower |

| Human operator safety | Higher | Lower |

| Consistency of quality | Higher | Lower |

In addition to being the largest abrasive blasting machine ever shipped by Gibson, the TB120XT is engineered with several features of convenience, including:

- Mechanical lift gate and crane slot allowing for large parts to be positioned in the center of the blast zone using a fork truck or hoist.

- Dual door setup allows for full access to the front of the table for ease of part loading

- Safety interlocks on the access doors only allow for sequential post-processing access

- Table rotation speed is controlled by variable frequency drives (VFD)

- Extra tall chamber with four individually controlled 30 HP direct drive blast wheels

Automated wheel blast equipment of this size provides the mature abrasive blasting industry with an exciting new alternative that satisfies a high demand in the industry for alternatives to the incumbent air blast room technology. Experience the difference of the TB120XT when considering a new or replacement blast room.

Contact Us to learn more about Automated Wheel Blast alternatives to Air Blast Rooms