Best In Class USA Manufacturer of Premium Abrasive Blasting Equipment

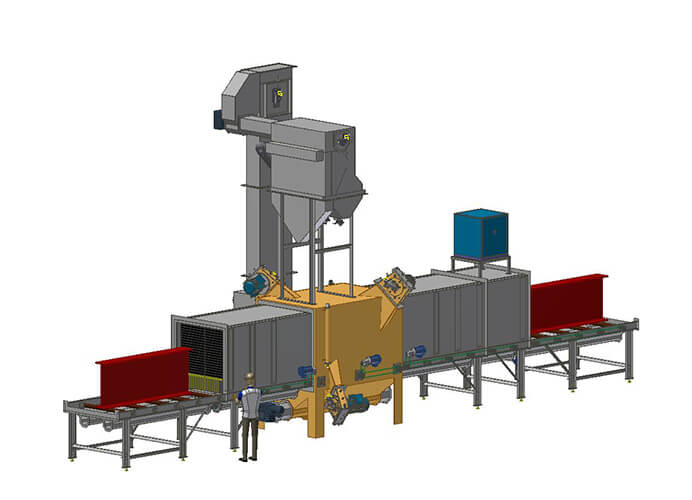

We are a leader in wheel-blasting technology, including equipment solutions for shot blasting, shot peening, and customized engineered systems

The optimal shot-blast equipment solution starts with a discussion about your surface preparation requirements and a proposed processing method. As an original equipment manufacturer, we forge strong relationships with many premier companies. We offer short lead-times, unbiased processing recommendations and an experienced staff to assist in every phase from design to completed orders. For over 20 years, Gibson has been a trusted partner in the wheel blast equipment industry. Our 100% focus on shot-blasting solutions has made us very good at what we do.

A Sample of Our Customers

Latest News

In our space of producing world-class Abrasive Wheel Blast equipment everything begins with our customer…. Abrasive Wheel Blast Automation Explained While we may have our own thoughts and extensive capabilities on what automation is, it really depends on what our customer’s definition is. From application, to part, to production targets, the open communication on …

Read more

Up until now, air blast rooms have long been the industry standard for abrasive blasting of large parts up to 10’ x 12’ simply due to the scalability offered when enclosing the human operator within the blast chamber. But at Gibson we like to ask, “What if there is a better way?” The answer is …

Read more

Expedite cleaning, peening, deburring, profiling, finishing and many other surface conditioning tasks! Gibson’s new TB120 Table Blast System takes the operator out of the blast room. The system features a 120” diameter, 10,000 lb. capacity manganese steel turntable, a ¼” thick steel front swing door, and two 15” diameter 20 HP Direct Drive Blast Wheels. …

Read more