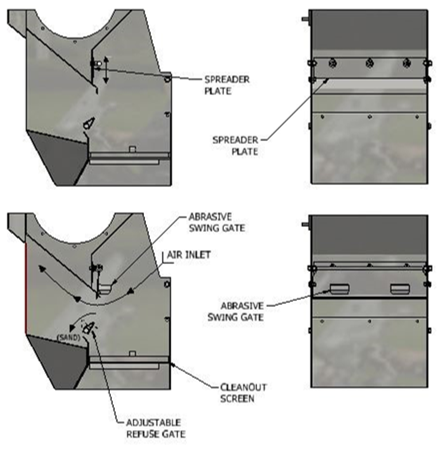

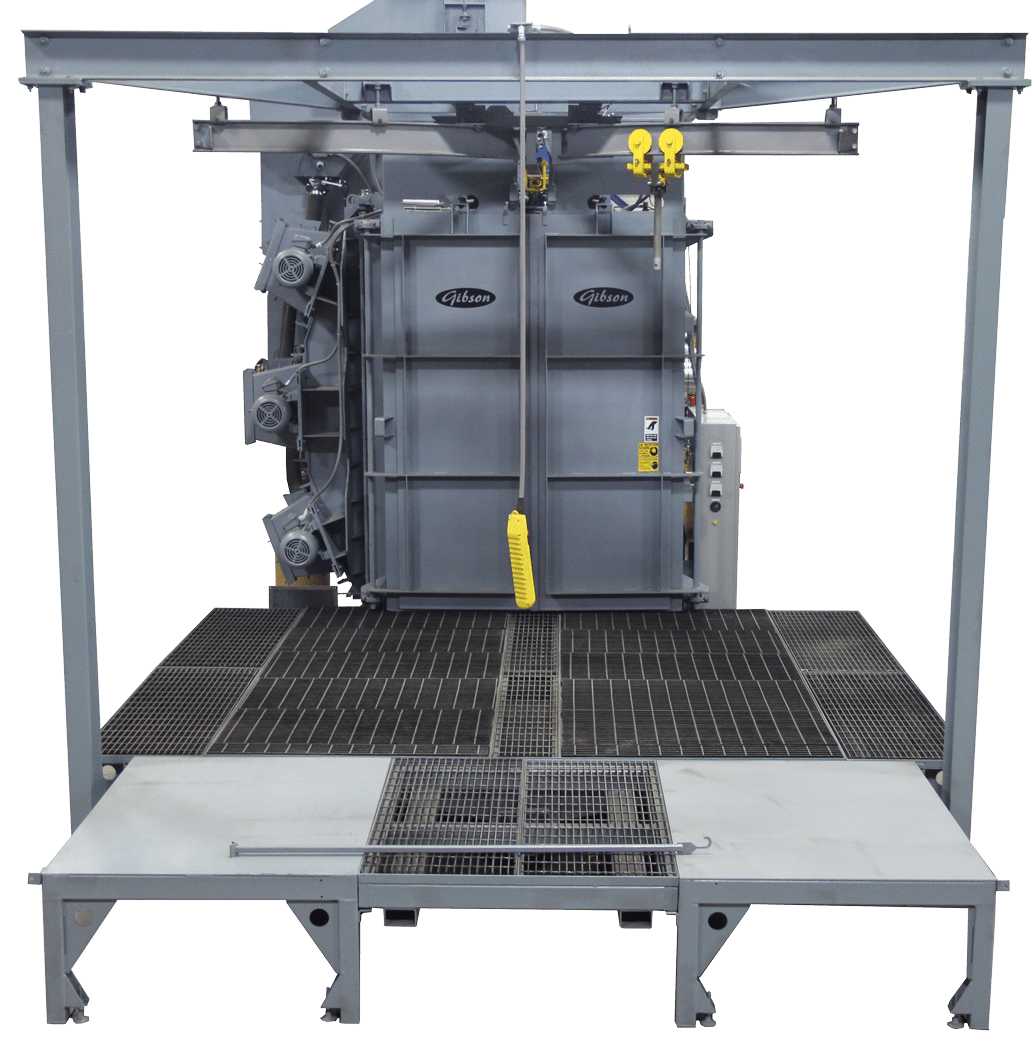

Products Spotlight – Gibson 84XT Standard Table Blast System

A wealth of knowledge and experience in sales, service and manufacturing has contributed to the steady success of our company. Our product line is continually expanding to meet the needs and challenges of the marketplace. The quality of our equipment, coupled with competitive pricing, has captured the attention of the shot blast industry. The Gibson …

Read more