The purpose of the Abrasive Separator is to separate sand, fines, and tramp metal from used abrasive, and filter out abrasive particles that are too small to use, which helps to ensure an optimal abrasive mix. This separation takes place before the usable abrasive is deposited into the Abrasive Storage Hopper for delivery to the Blast Wheel. To function properly the Abrasive Separator must have adequate air flow.

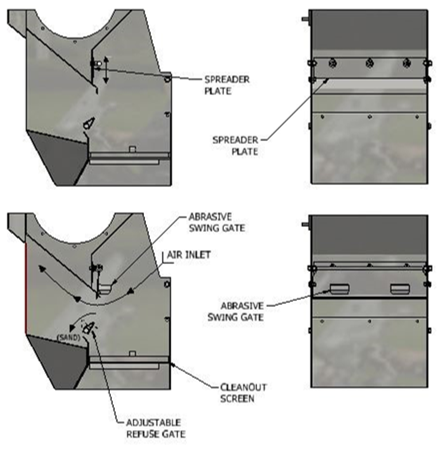

The abrasive falls against an adjustable Spreader Plate. This gate should be adjusted up or down to spread the abrasive across the width of the Separator. If the spreader plate restricts the flow of abrasive, the abrasive will backfill and overwhelm the elevator. When this occurs, the spreader plate should be raised slightly to allow more abrasive flow.

If there is a consistent hole in the curtain, something might be obstructing the flow of abrasive. Clean out the obstruction and check all screens for wear.

After adjusting the spreader plate, it is time to adjust the abrasive gate. The abrasive gate is used to apply pressure against the abrasive. The more pressure applied the thinner the curtain, and the thinner the curtain, the more air can flow through the abrasive. The size of the abrasive determines the thickness of the Abrasive Curtain. When a large size abrasive mixture is used, the thickness of the curtain should be decreased. With a finer abrasive mixture, the thickness should be increased. Spreader plate and blast gate adjustment will vary depending on abrasive size, material to be blasted, and operating environment. Always maintain an even flow of abrasive in the curtain. The air-wash separator can’t work properly unless the dust collector is properly maintained. All Gibson dust collectors are equipped with a differential pressure gauge, allowing you to easily verify the integrity of the filters and dust collector condition.

After adjusting the spreader plate, it is time to adjust the abrasive gate. The abrasive gate is used to apply pressure against the abrasive. The more pressure applied the thinner the curtain, and the thinner the curtain, the more air can flow through the abrasive. The size of the abrasive determines the thickness of the Abrasive Curtain. When a large size abrasive mixture is used, the thickness of the curtain should be decreased. With a finer abrasive mixture, the thickness should be increased. Spreader plate and blast gate adjustment will vary depending on abrasive size, material to be blasted, and operating environment. Always maintain an even flow of abrasive in the curtain. The air-wash separator can’t work properly unless the dust collector is properly maintained. All Gibson dust collectors are equipped with a differential pressure gauge, allowing you to easily verify the integrity of the filters and dust collector condition.

Maintaining a full curtain width and proper thickness is extremely important to equipment functionality and life span. Contact a Gibson customer service representative to schedule a visit from a Gibson technician.