Pipe Blast System

Features:

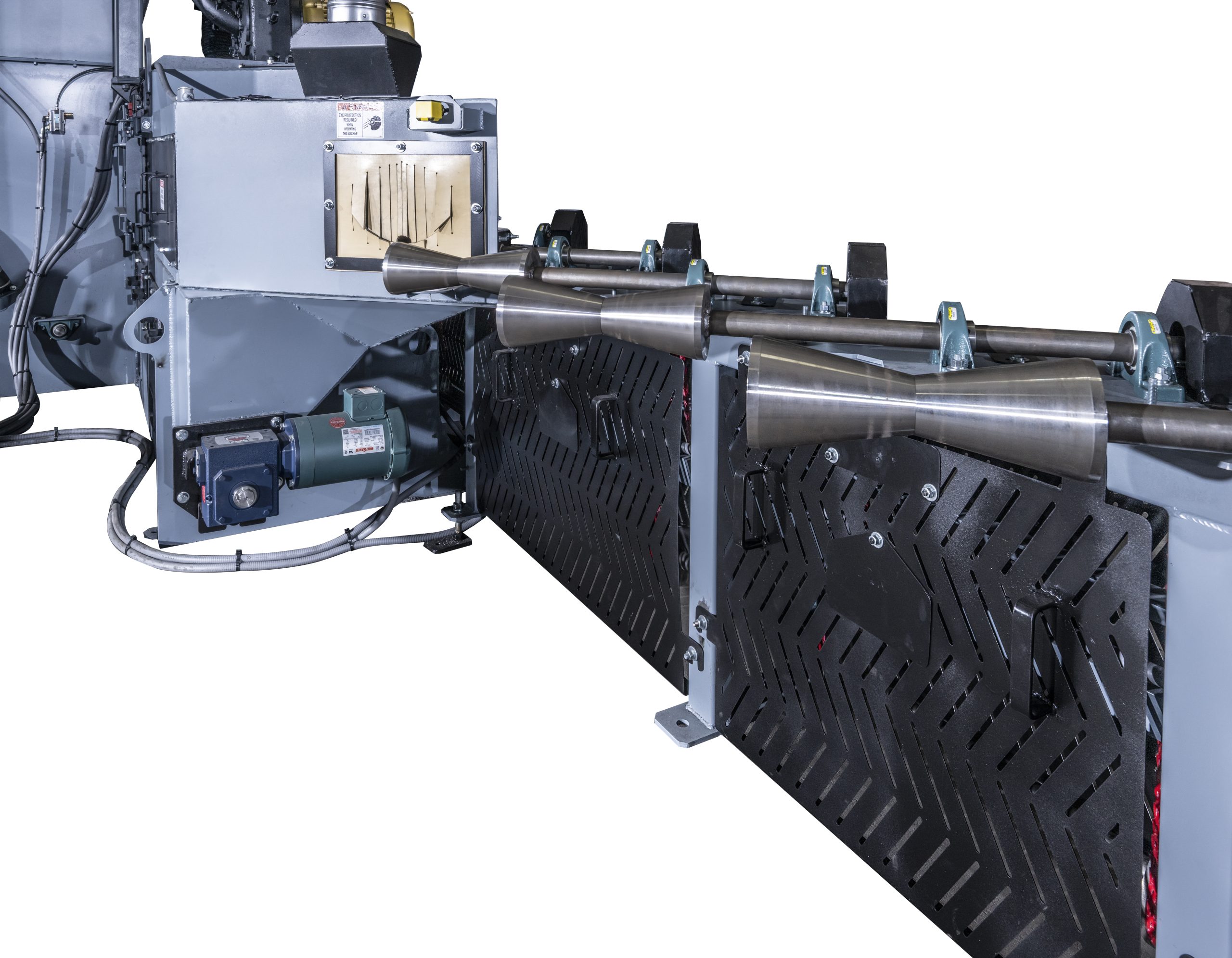

- These are fully automated machines designed for cleaning pipe and other long and round materials.

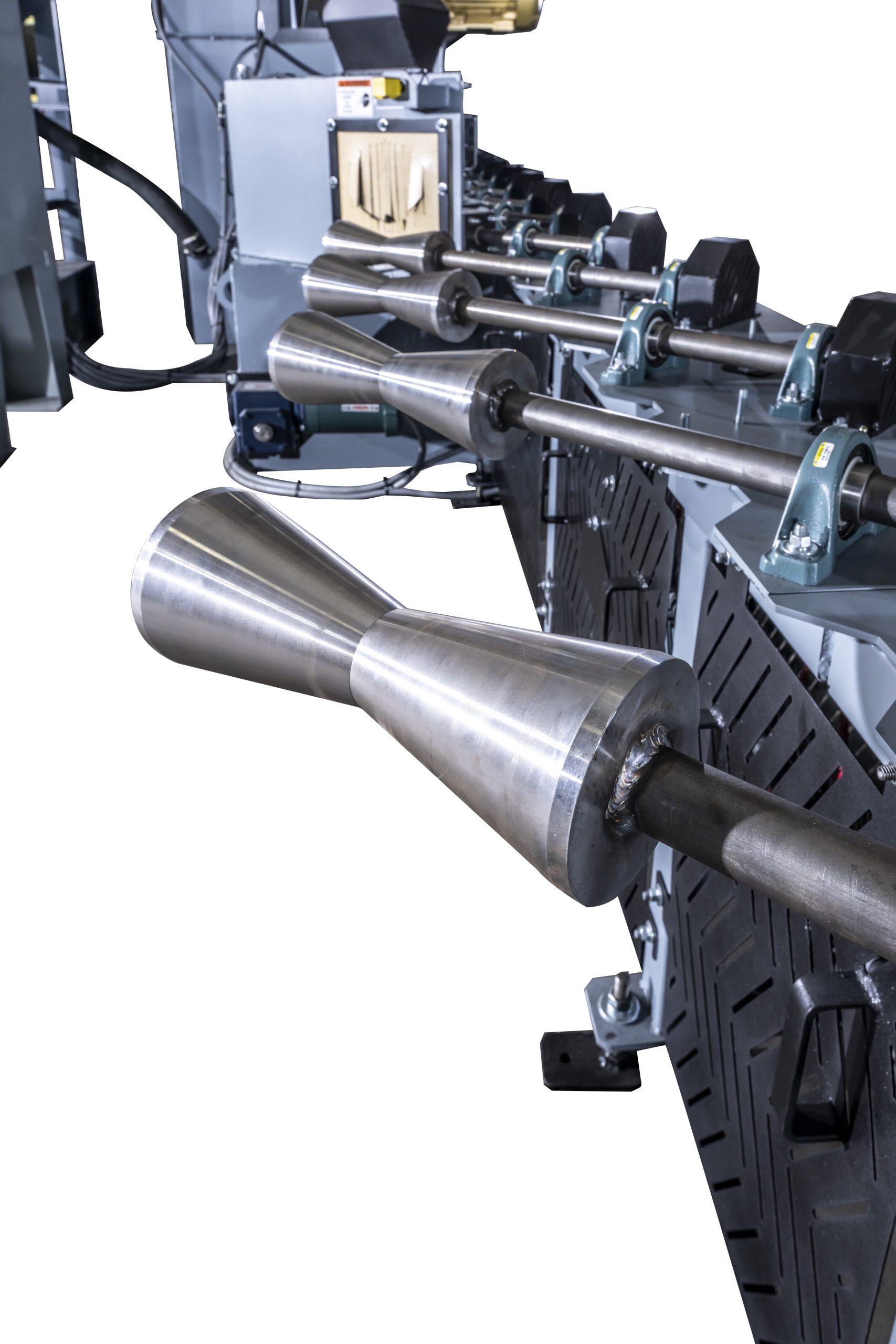

- Skew roll conveyor that rotates parts 360 degrees as they travel through the blast chamber.

- Designed to remove rust and mill scale and create a surface profile for coating adhesion.

- Can handle pipe up to 42″ in diameter.

- Modular roller conveyors to accommodate different pipe lengths.

- Sensors control the flow of media to only blast when a pipe is present.

- 3/8″ manganese steel blast chamber with cabinet liner packages of rubber, AR400 plate, manganese steel, or cast chrome alloy.

- HMI controls to adjust the process and control the finish.

Benefits:

- Ideal for industries that repurpose used pipes, such as oil and gas, construction, and chemical processing.

- Ensure the entire surface of all pipes is fully cleaned.

- Save costs on wear parts and extend the life of the machine.

- Remove dust and mill scale and create a surface profile ready for coating.