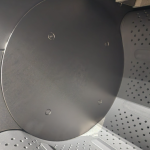

The heart of any wheel blast machine is its blast chamber, where abrasive media powerfully impacts your parts. To protect this critical area from the intense direct blast and ensure long-term machine life, high-quality liners are essential. At Gibson, we offer a range of liner kits designed to meet diverse blasting needs.

What are Liners and Why Do They Matter?

Liner packages are designed to cover and protect your blast chamber walls and internal components from the direct intensity of the abrasive blast. High-wear areas, especially the cabinet side opposing the blast wheel, are covered by these liners.

Gibson’s Liner Kit Options: From Standard to Specialized

We offer several types of liner materials, each with unique properties, to accommodate different blast processes and media types:

- Rubber: Our standard option, versatile and effective with various media.

- Abrasion Resistant (AR): Provides good wear resistance against all media types.

- Manganese: Offers enhanced durability as it work-hardens under impact.

- Cast Iron / Cast Chrome Alloy: Extremely tough for demanding applications.

- Specialty Liners (e.g., Stainless Steel): Available by request for unique needs, such as preventing contamination when blasting stainless steel parts with stainless steel media. We have the engineering and manufacturing capabilities to meet specific customer requirements for these specialized liners.

Liner kit options are clearly outlined on all our quotes.

Key Benefits of Choosing the Right Liner:

-

- Contamination Control: For customers processing materials like stainless steel, specific liners (e.g., stainless steel liners) prevent foreign contaminants from carbon media or liners from affecting the part.

- Optimized Wear Resistance: Different liner materials hold up better against specific media types, whether it’s shot, cut wire, or grit. Hardness is a primary factor in selection.

- Reduced Maintenance: By protecting the cabinet from direct blast, liners reduce wear and tear, contributing to lower maintenance and repair costs.

Modular, Easy to Maintain, and Always in Stock

Our liners are a congruent series of modular, such as 12×12 inch square components, typically 1/2 inch thick. They are designed for easy replacement – simply unscrew a nut, remove the worn liner, and install a new liner.

A key design feature is their “shiplap” fit, where individual plates interlock without seams. This labyrinth design prevents blast media or debris from getting through to the cabinet walls, offering superior protection.

We keep all types and sizes of these modular liners fully stocked at Gibson for on-demand shipping, ensuring you can get replacements quickly when needed. While typically very durable, liners should be replaced if you notice chips or breaks.

Every new Gibson machine comes with a liner kit, and all liner types are fully interchangeable. This means you can swap materials (e.g., from rubber to a harder material) for future projects using the same mounting and maintenance process.

Contact Us today to discuss the best liner options for your specific blasting needs and media types.