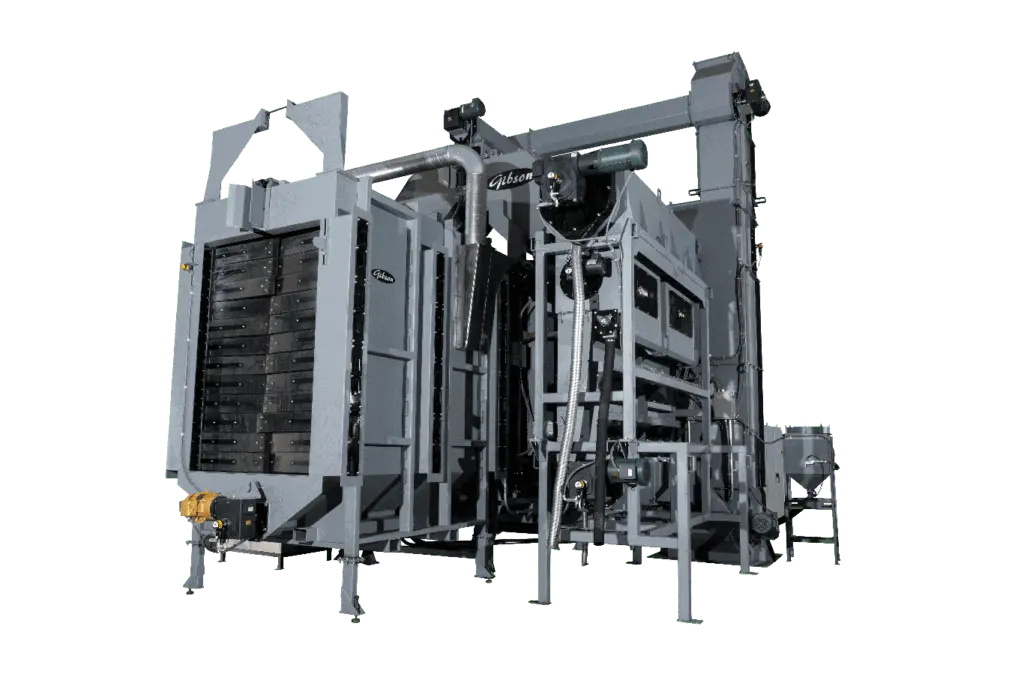

Monorail Blast System

Features:

-

- These are fully automated systems designed for continuous 24-hour flow production.

- Can be customized to accommodate specific blasting needs.

- Manganese blast cabinets and cast alloy liners.

- Entrance and exit vestibules for abrasive containment.

- Multiple blast wheels positioned for optimum coverage.

Benefits:

-

- Ideal for high production rates of large fabrications, heavier parts, and cast parts.

- Automate cleaning or removing flash from die-cast parts.

- Streamline the shot blast process.

Applications: Blasting of Heavier Parts or Components | Cast Parts | External Finishing | High Production Rates | Large Fabrications | Sand Removal

Product Details

| Key Features | Continuous Flow Production |

|---|---|

| Factory Options | Automatic Abrasive Blow Off System |

| Customization | Control Options and Part Recipes |