Wheel or Air Blasting Stainless Fabrications?

Most stainless blast applications are done utilizing air blast delivery methods. Air blast could require an operator reaching into a blast cabinet or operating inside a blast room. The use of stainless shot or grit in a wheel blast system drastically cuts down on blast time, involvement from an operator, and overall operating costs.

Table Blast Systems efficiently blast heavy fabrications removing weld discoloration, leaving a clean and smooth surface.

Major Differences Between the Two Blast Delivery Systems:

Wheel Blasting Operating Principles

Abrasive Flow of 2,100 pounds per minute requires:

- One Operator

- (4) Blast Wheels @ 20 horsepower each

- Compressed air consumption 5.0 SCFM

- Compressor power 60 KW

- 80 horsepower

Advantages:

- Velocity of shot easily controlled through wheel speed.

- High flow rate of abrasive will provide high production.

- Economical – one 20 hp wheel can throw 525 lbs per minute equal to nearly seven 1/2” nozzles at direct pressure at 90 psi.

- Does not require very much compressed air.

- Low labor costs.

- Higher production rates.

- Complete coverage.

Disadvantages:

- Can damage delicate or thin parts.

- Not good for localized peening.

- Greater abrasive consumption.

- Can’t be used with aluminum oxide or glass bead.

Gibson 6BB Tumble Blast System – Fabricated Flanges – Blast Cleaning Wheel Blast

Gibson 36″ Power Table Blast System – Processing Stainless Fabrications

Air-Blasting Operating Principles

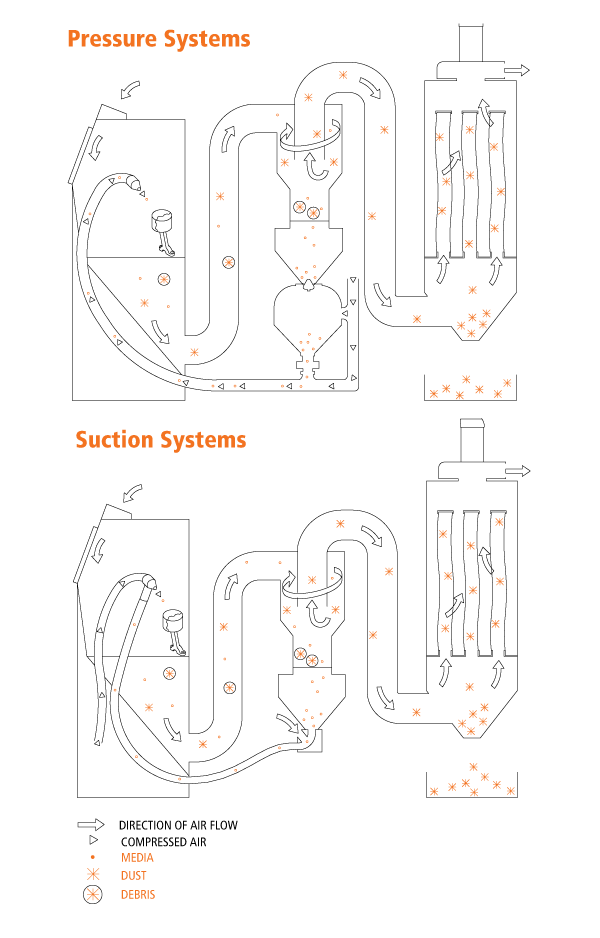

Blast media is pressurized in a blast tank or suctioned and propelled through a nozzle or multiple nozzles.

Abrasive Flow of 2,100 pounds per minute requires:

- (27) Operators

- (27) ½” Nozzles @ 90 PSI

- Compressed air consumption 8,370 SCFM

- Compressor power 1400 KW

- 1,876 Horsepower

Advantages:

- Great for localized peening or cleaning.

- Typically does not damage delicate or thin parts using the right media.

- Can be used with aluminum oxide & Glass Bead.

Disadvantages:

- Requires a lot of compressed air.

- High labor costs.

- Smaller blast pattern.

- Low production rates.

- Low abrasive flow rates.

Interested in making the switch? Contact Gibson Abrasive Equipment today and test parts in the process development lab.